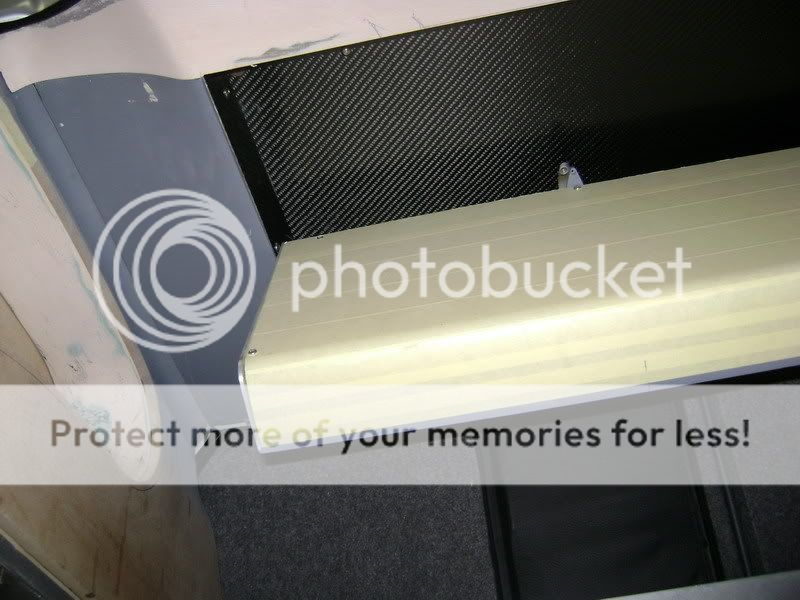

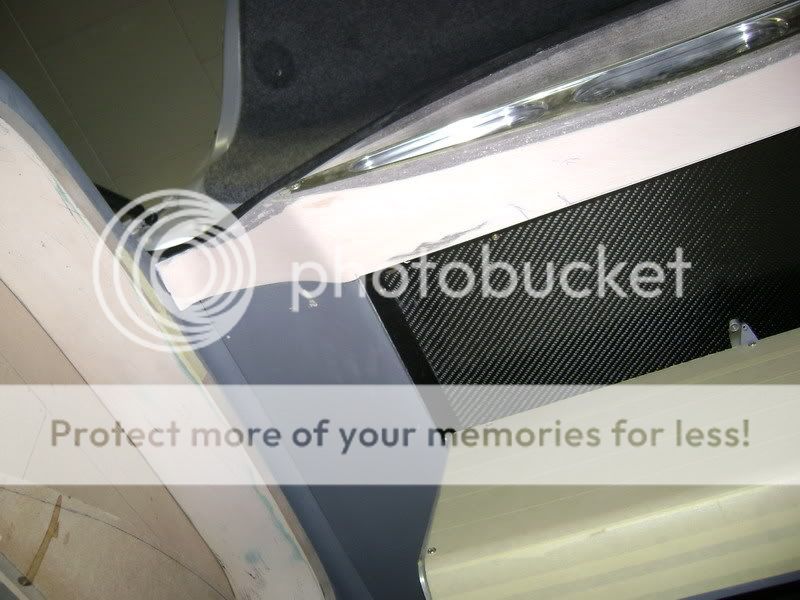

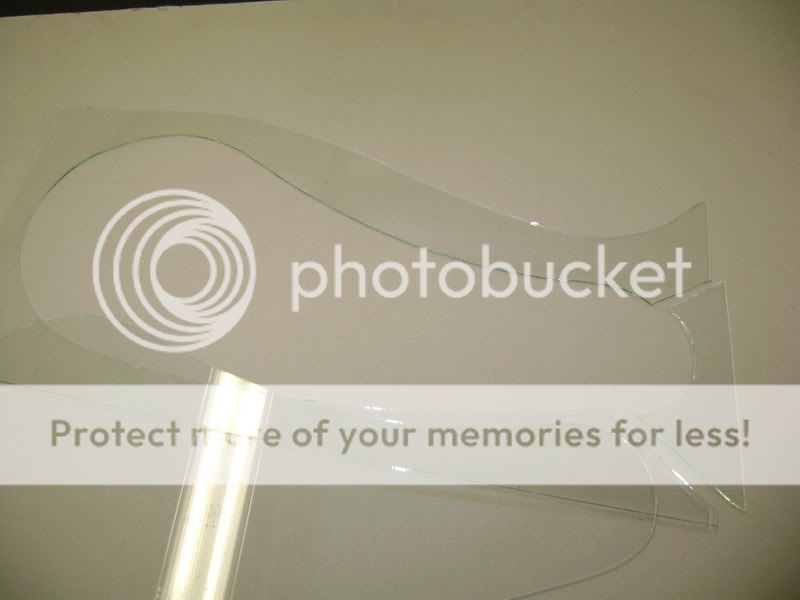

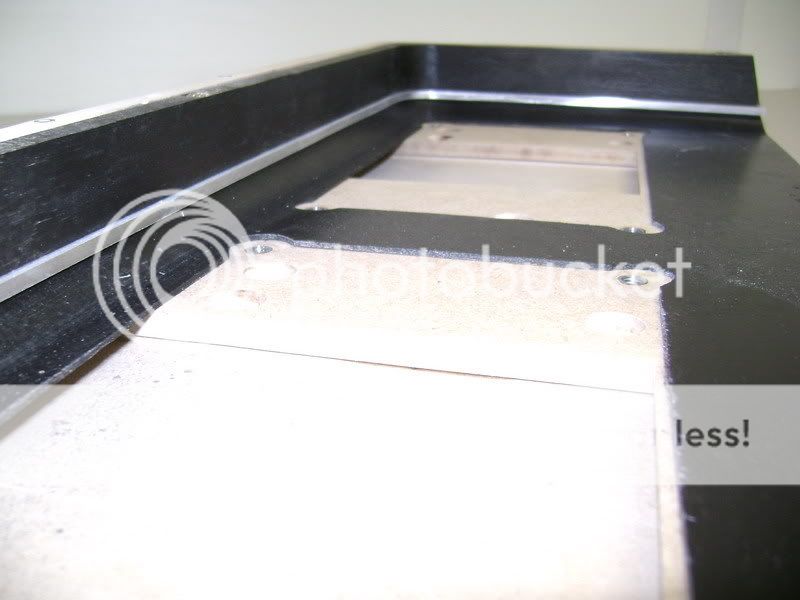

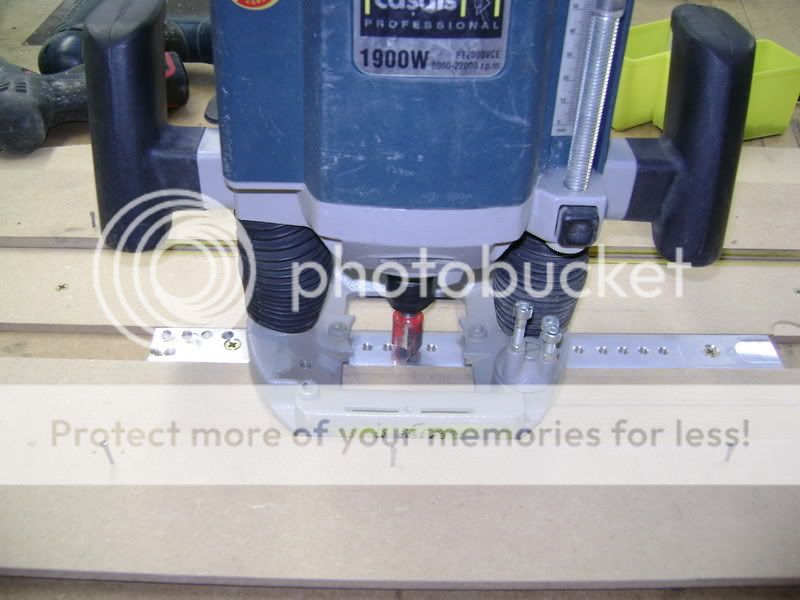

I have been following the install for a while over on the car sound forums.... Your fabrication skills make me crazy. My favorite part so far is the block of marble with sand paper from a floor sander to get a perfect flat surface. Just makes me smile. Your attention to detail are the types of things I strive for and other people should to. Thank you for taking thing to another level of taste and refinement. Still can't believe you plunge routered all that aluminum. I wish I had that kind of time.

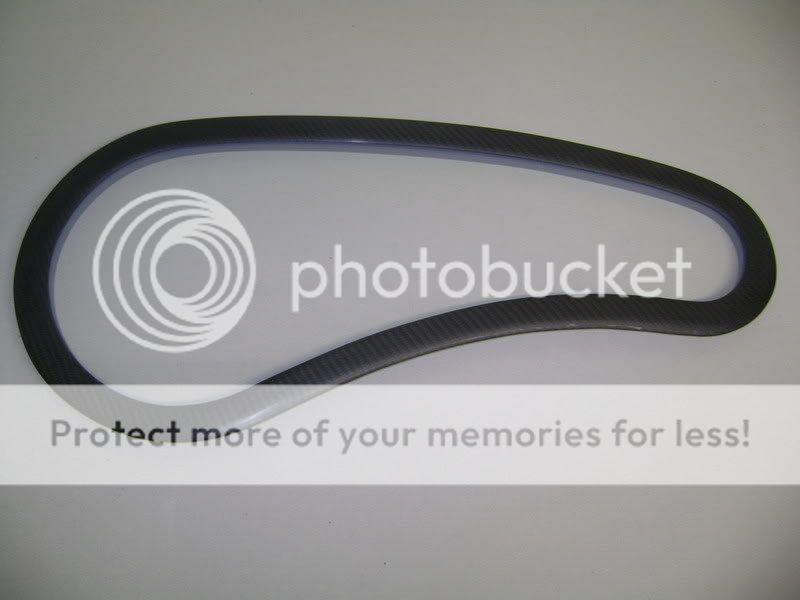

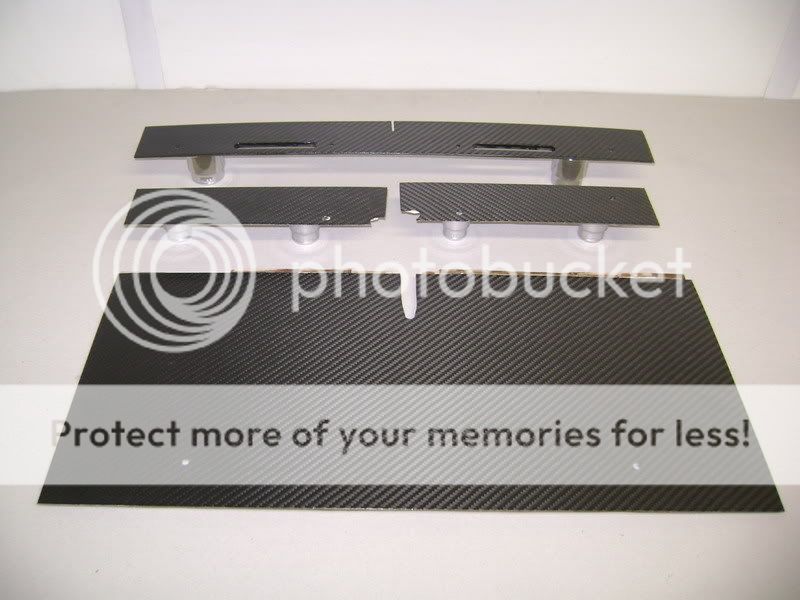

I did have one question when you resign your carbon fiber do you press it and heat it when its drying to get a smooth finish or do you float it on and just wet sand it up and clear it ?

Can't wait to see more !