So like many other people, I'm tired of wondering what CLD ACTUALLY works best. So I've decided to test a whole spectrum of them, using an accelerometer, so this can be put to rest. This will take between 1-2 months to start, but may be drawn out over time if people want continuing results from new products, etc. Once I have the test rig set up, it wont be that hard to test.

As of right now, I plan to build a box out of baltic birch. It will have two removable baffles, both secured with 10-32 screws, and hurricane nuts. The front baffle will hold two speakers, which will remain unchanged throughout the testing. This will be HAT L6SE's. There will be two front baffles, one completely sealed, aside from speaker mounting holes, and one with two 2" vent holes. The reason for this, is that a sealed box will cause different levels of vibration than one that is just measuring structural vibration, and I want both measurements.

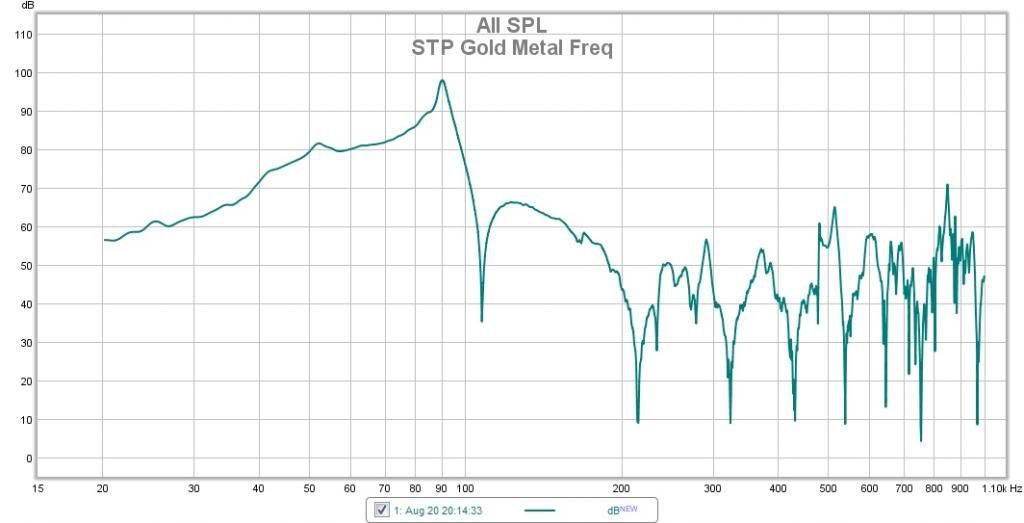

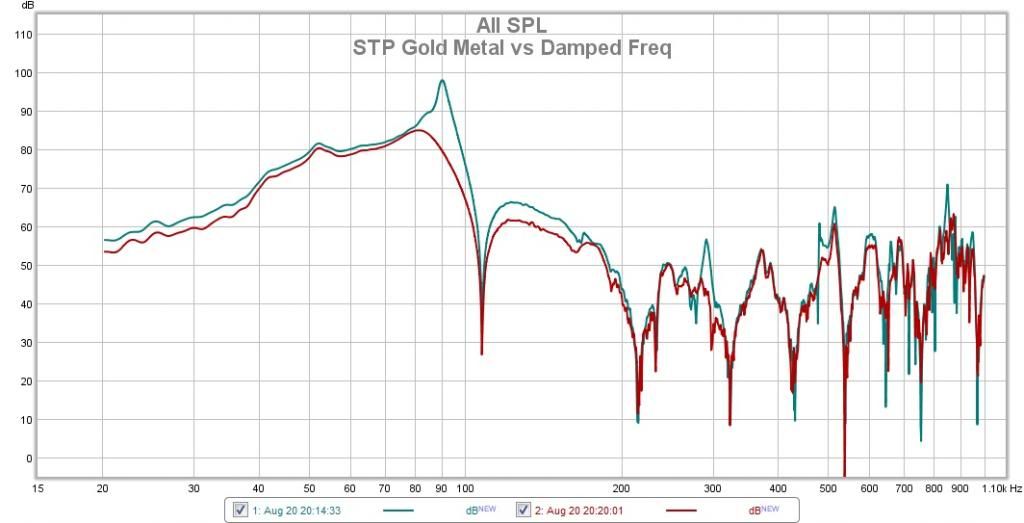

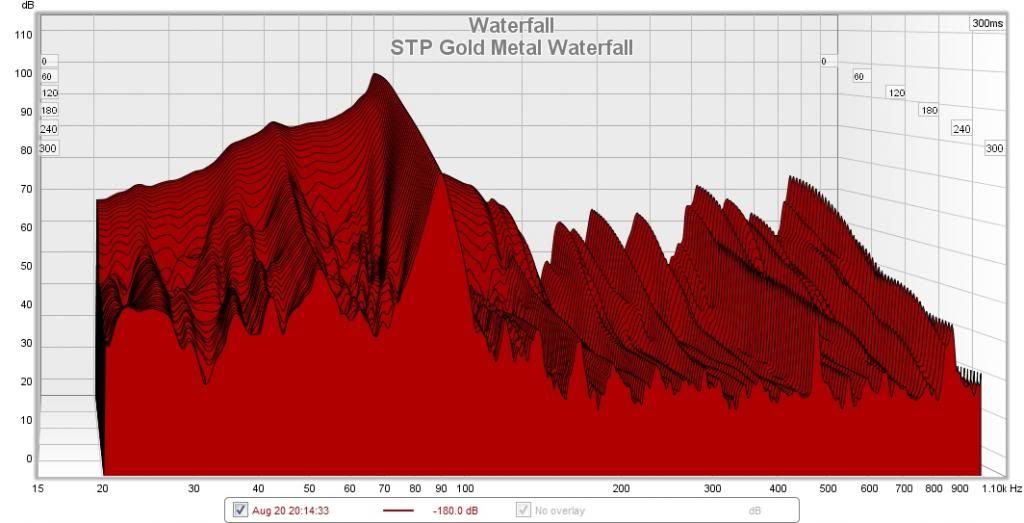

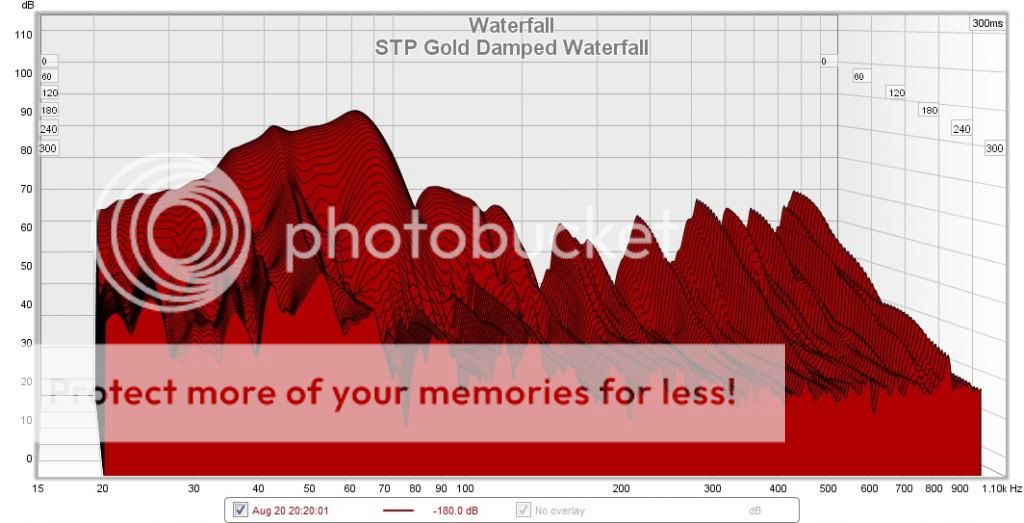

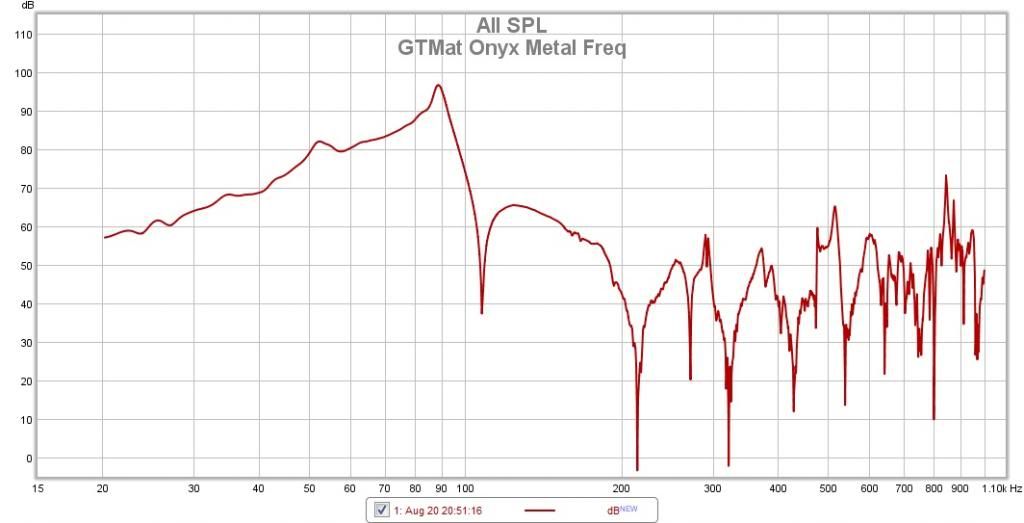

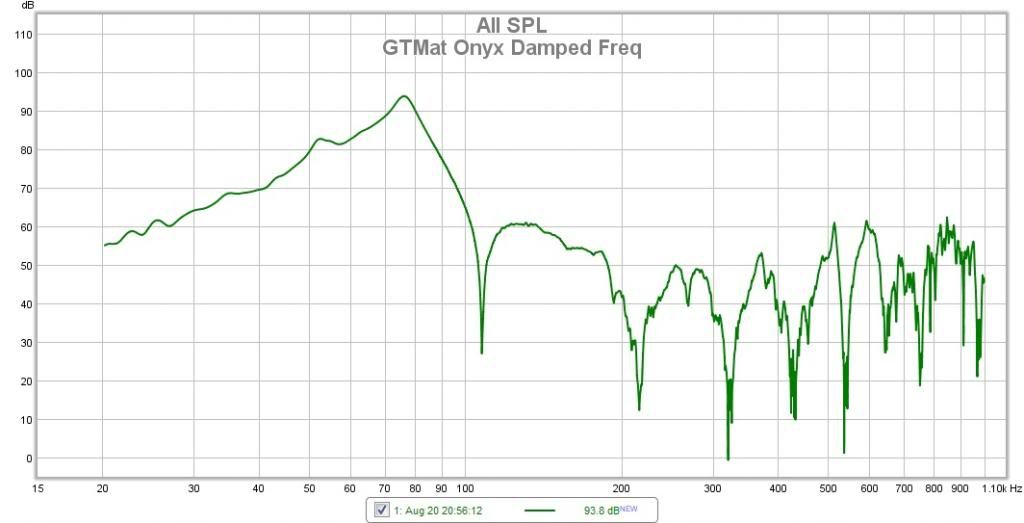

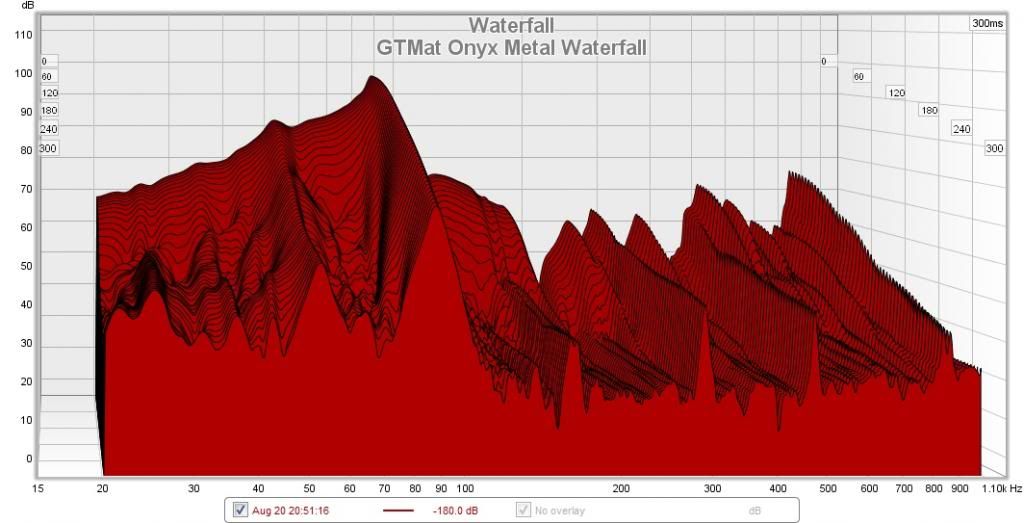

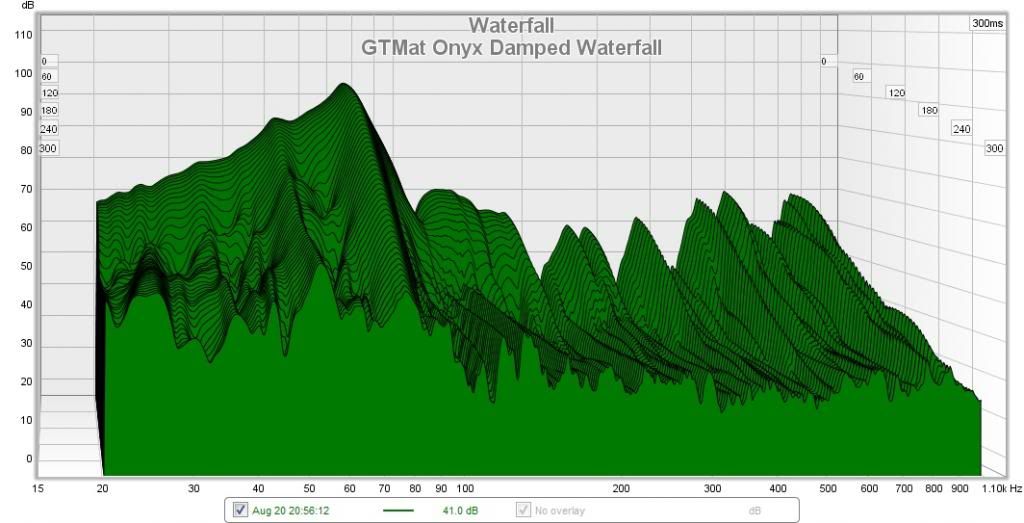

The back baffle will be 22ga 12" squares of mild steel. There will be a new piece of steel for each different CLD. The reason is, removing this stuff could result in bends, and that could change resonant frequency of the baffle. So each CLD test will get its own piece of metal, and each will have before and after measurements, so that deadener effectiveness can be seen as a percentage. I will also post the frequency response of each test, if possible (I need to check one what kind of output I can get from my O-Scope, more on that by friday). Each panel will be bolted on at a set torque with a calibrated torque wrench, to keep that from being an issue. The piece will have a 1/2" perimeter to be bolted down to.

Each CLD piece will be weighed, measured, and photographed multiple times pre and post installation. I may also take video of each test. Samples will all be 6x6" squares, just a tad bit over 25% coverage. Testing will be done indoors, and will be temperature controlled.

I'm open to durability testing, but using the oven is out. New house, and not quite ours yet, means thats not going to happen. I have a torch, but thats a little inconsistent. It does get ridiculously hot here in the summer, I could save all the pieces, then leave them out when its 110 degrees for a week or so.

Once I've gone through the testing to "rank" the deadeners, I will move on to some intall technique tests/alternative deadening techniques tests. Things such as seeing what kind of differences to expect going from 25% coverage to 50% coverage, etc. I'd also like to test using small pieces vs on large equal area sheet. I've seen it suggested that small pieces randomly spaced works just as well, I'd like to prove or disprove that. Then I'd like to test bracing, and bracing+deadening, etc.

If anyone has an input, feel free to let me know. I'd like to get this issue settled.

If anyone wants to donate products, they are more than welcome, I'll post in the first post what I have, and whats been donated, and by who, unless they wish to remain anonymous. All I ask is that pieces donated are 6x6" squares or larger.

I've updated what people might be able to send so far. I want to make sure no one feels any pressure or rush, the soonest I forsee being able to start actually testing is the beginning of May. When I get products in, I'll move them to the corresponding area. I will also start to build the test enclosure this weekend.

Dynamat xtreme - 1 12"x12"

GTMat Pro 50 Mil - 1 12"x12"

GTMat Ultimate 80 Mil - 1 12"x12"

GTMat 110 Mil - 1 12"x12"

GTMat Onyx - 1 12"x12"

Alphadamp - 1 10"x14"

SDS CLD - 1 6"x10"

Stinger Road Kill Pro - 2 6"x6"

Lightning Audio Deadskin - 1 8"x8"

StP Bomb - 1 sheet

StP Gold - 1 sheet

StP Silver - 1 sheet

StP Vizomat - 1 sheet

Peel N Seal - 1/3 Roll

Things that are on the way or have might soon be on the way

Fatmat

second skin damp pro

edead

possibly some cascade V-2

possibly some knu concepts stuff

That leaves me wanting for the test

cascade vmax

maybe some raamat

As of right now, I plan to build a box out of baltic birch. It will have two removable baffles, both secured with 10-32 screws, and hurricane nuts. The front baffle will hold two speakers, which will remain unchanged throughout the testing. This will be HAT L6SE's. There will be two front baffles, one completely sealed, aside from speaker mounting holes, and one with two 2" vent holes. The reason for this, is that a sealed box will cause different levels of vibration than one that is just measuring structural vibration, and I want both measurements.

The back baffle will be 22ga 12" squares of mild steel. There will be a new piece of steel for each different CLD. The reason is, removing this stuff could result in bends, and that could change resonant frequency of the baffle. So each CLD test will get its own piece of metal, and each will have before and after measurements, so that deadener effectiveness can be seen as a percentage. I will also post the frequency response of each test, if possible (I need to check one what kind of output I can get from my O-Scope, more on that by friday). Each panel will be bolted on at a set torque with a calibrated torque wrench, to keep that from being an issue. The piece will have a 1/2" perimeter to be bolted down to.

Each CLD piece will be weighed, measured, and photographed multiple times pre and post installation. I may also take video of each test. Samples will all be 6x6" squares, just a tad bit over 25% coverage. Testing will be done indoors, and will be temperature controlled.

I'm open to durability testing, but using the oven is out. New house, and not quite ours yet, means thats not going to happen. I have a torch, but thats a little inconsistent. It does get ridiculously hot here in the summer, I could save all the pieces, then leave them out when its 110 degrees for a week or so.

Once I've gone through the testing to "rank" the deadeners, I will move on to some intall technique tests/alternative deadening techniques tests. Things such as seeing what kind of differences to expect going from 25% coverage to 50% coverage, etc. I'd also like to test using small pieces vs on large equal area sheet. I've seen it suggested that small pieces randomly spaced works just as well, I'd like to prove or disprove that. Then I'd like to test bracing, and bracing+deadening, etc.

If anyone has an input, feel free to let me know. I'd like to get this issue settled.

If anyone wants to donate products, they are more than welcome, I'll post in the first post what I have, and whats been donated, and by who, unless they wish to remain anonymous. All I ask is that pieces donated are 6x6" squares or larger.

I've updated what people might be able to send so far. I want to make sure no one feels any pressure or rush, the soonest I forsee being able to start actually testing is the beginning of May. When I get products in, I'll move them to the corresponding area. I will also start to build the test enclosure this weekend.

Dynamat xtreme - 1 12"x12"

GTMat Pro 50 Mil - 1 12"x12"

GTMat Ultimate 80 Mil - 1 12"x12"

GTMat 110 Mil - 1 12"x12"

GTMat Onyx - 1 12"x12"

Alphadamp - 1 10"x14"

SDS CLD - 1 6"x10"

Stinger Road Kill Pro - 2 6"x6"

Lightning Audio Deadskin - 1 8"x8"

StP Bomb - 1 sheet

StP Gold - 1 sheet

StP Silver - 1 sheet

StP Vizomat - 1 sheet

Peel N Seal - 1/3 Roll

Things that are on the way or have might soon be on the way

Fatmat

second skin damp pro

edead

possibly some cascade V-2

possibly some knu concepts stuff

That leaves me wanting for the test

cascade vmax

maybe some raamat