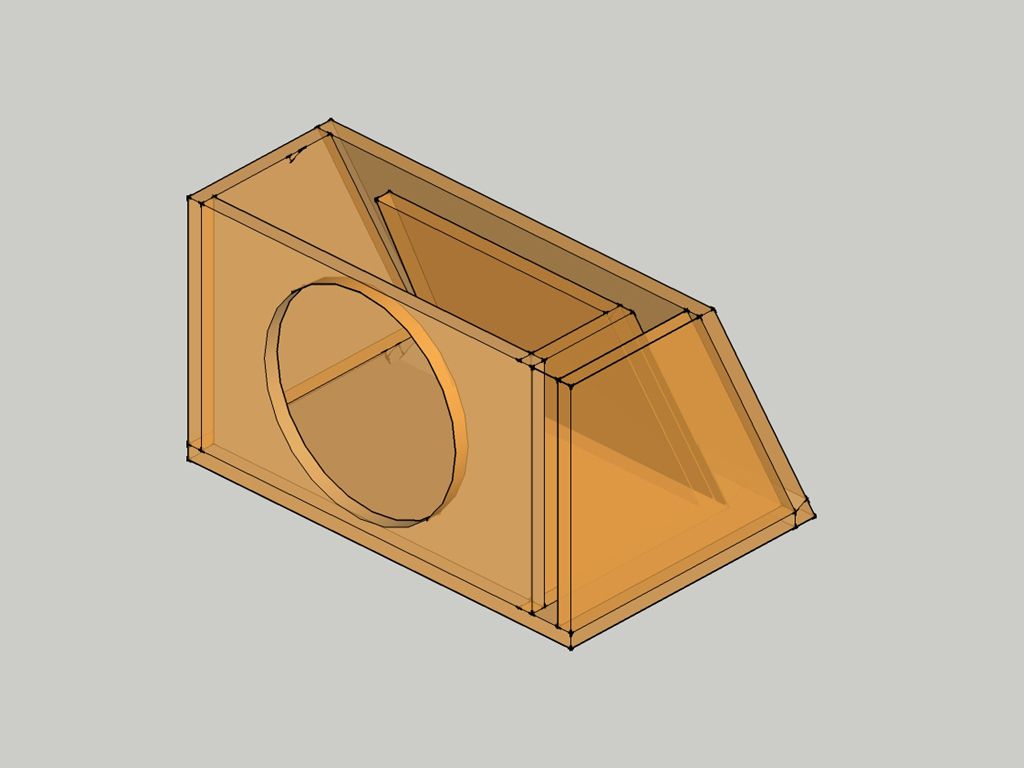

I'm working on a design for a ported box that has a angled back.

The sub will be on the top of the box and the port will be on the front.

Are there any weird calculations I need to do for the slot port, since the port would be running along one straight sides of the box, then along the back which has the angle?

Thanks.

The sub will be on the top of the box and the port will be on the front.

Are there any weird calculations I need to do for the slot port, since the port would be running along one straight sides of the box, then along the back which has the angle?

Thanks.