Been a while since I've posted a build - the SQ scene is dead where I'm from, so I kind of stepped over to the dark (SPL) side just to keep involved in car audio. The truck I'm building had some engine issues recently though so I pulled it off the road to fix them, along with some rust issues. I needed a daily driver in the meantime so I picked up this '94 Cavalier for a princely sum of $400.

The standard AC Delco cassette deck and speakers leave a lot to be desired aurally, so I figured it's time to dust off some of my old school car audio collection and put it to use where it belongs! So the plan is this:

Source:

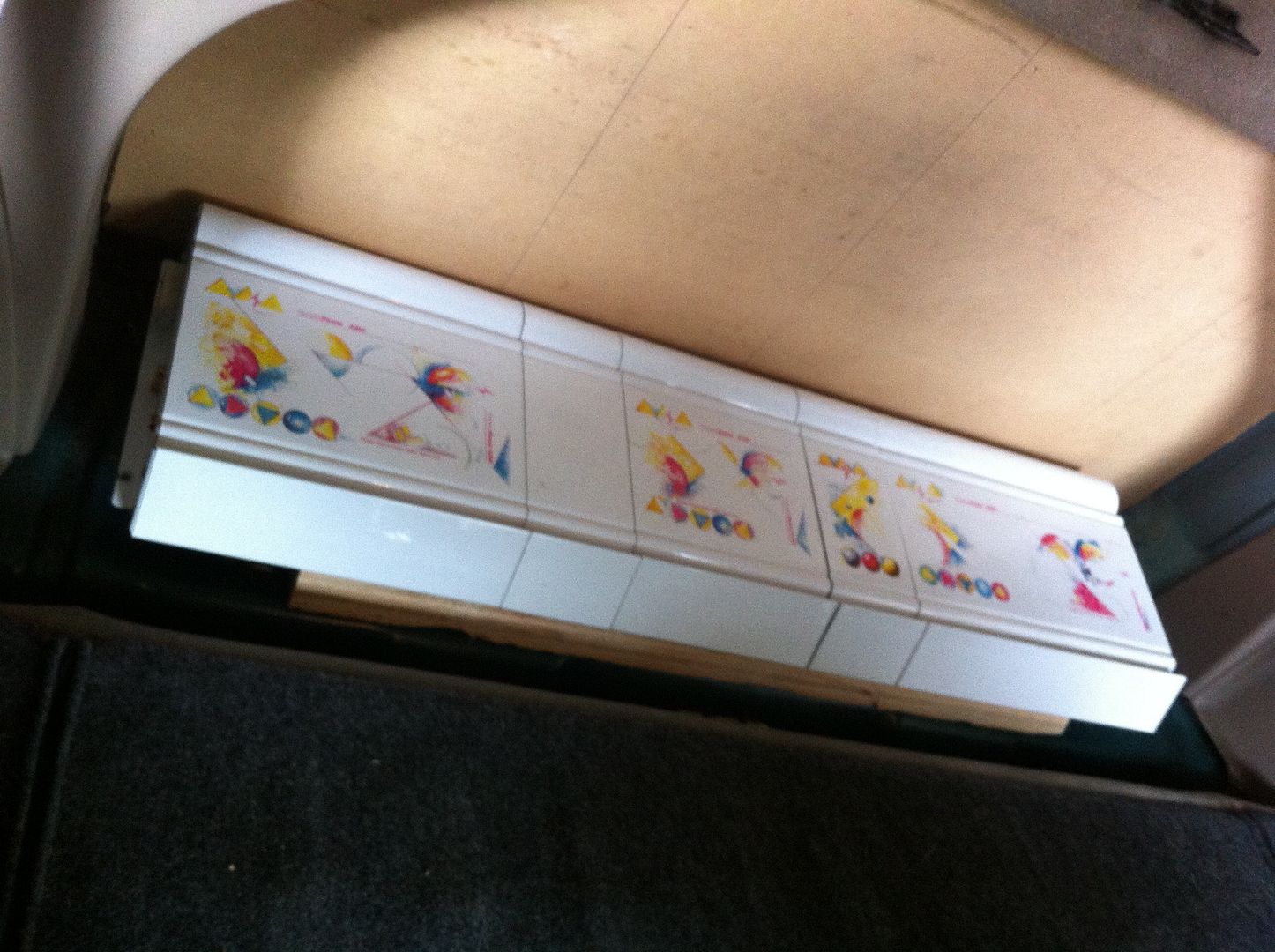

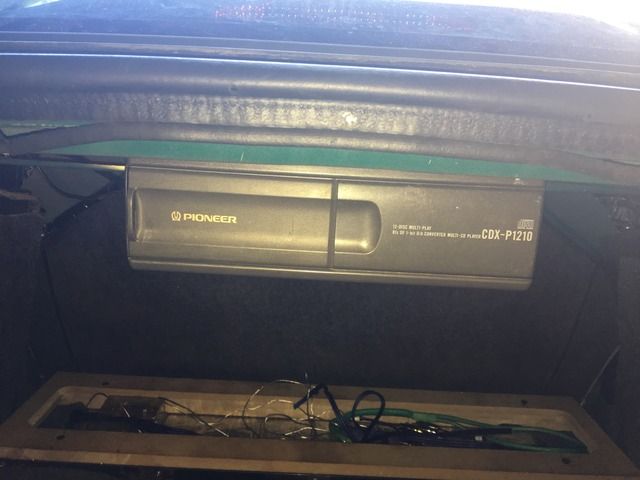

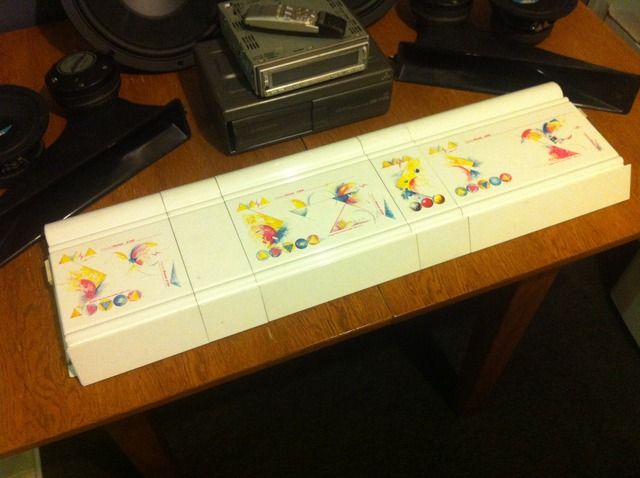

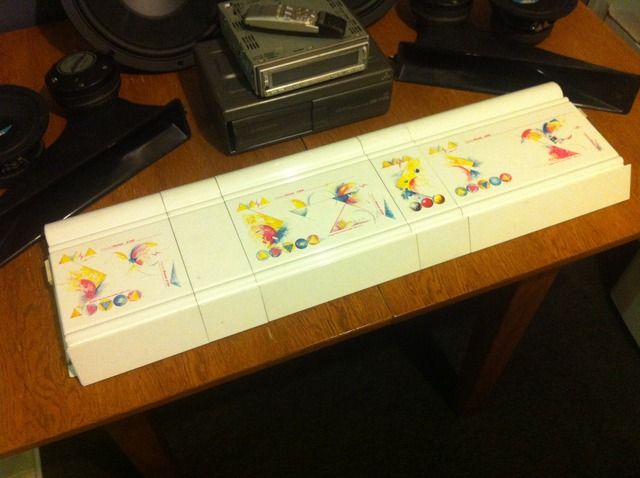

Pioneer DEX-P1 with CDX-P1210 12 disc CD changer

Amplification/Speakers:

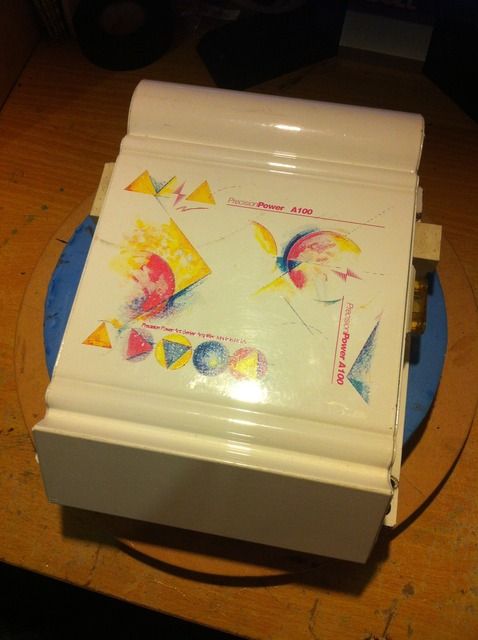

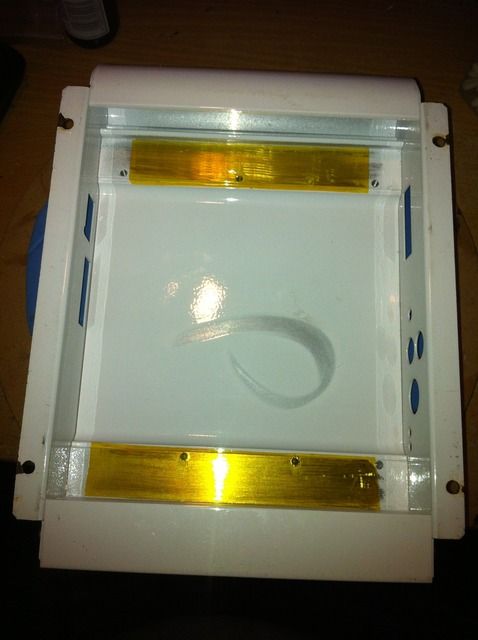

Highs - Image Dynamics CD-1 HLCD's with early fibreglass bodies on a PPI A100

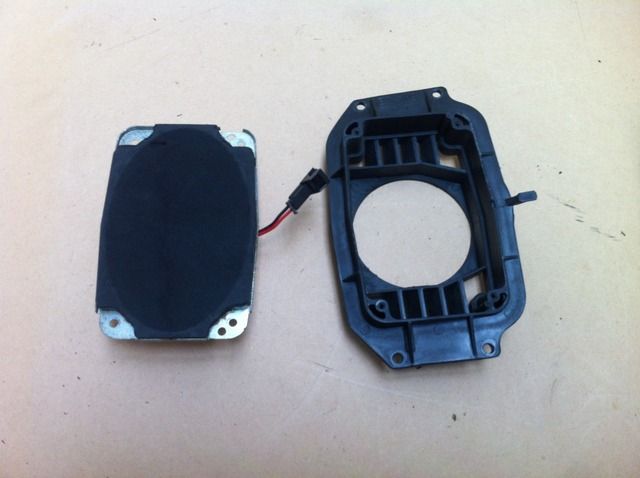

Mids - Image Dynamics IDQ62 6.5" 2-Ohm drivers on a PPI A200

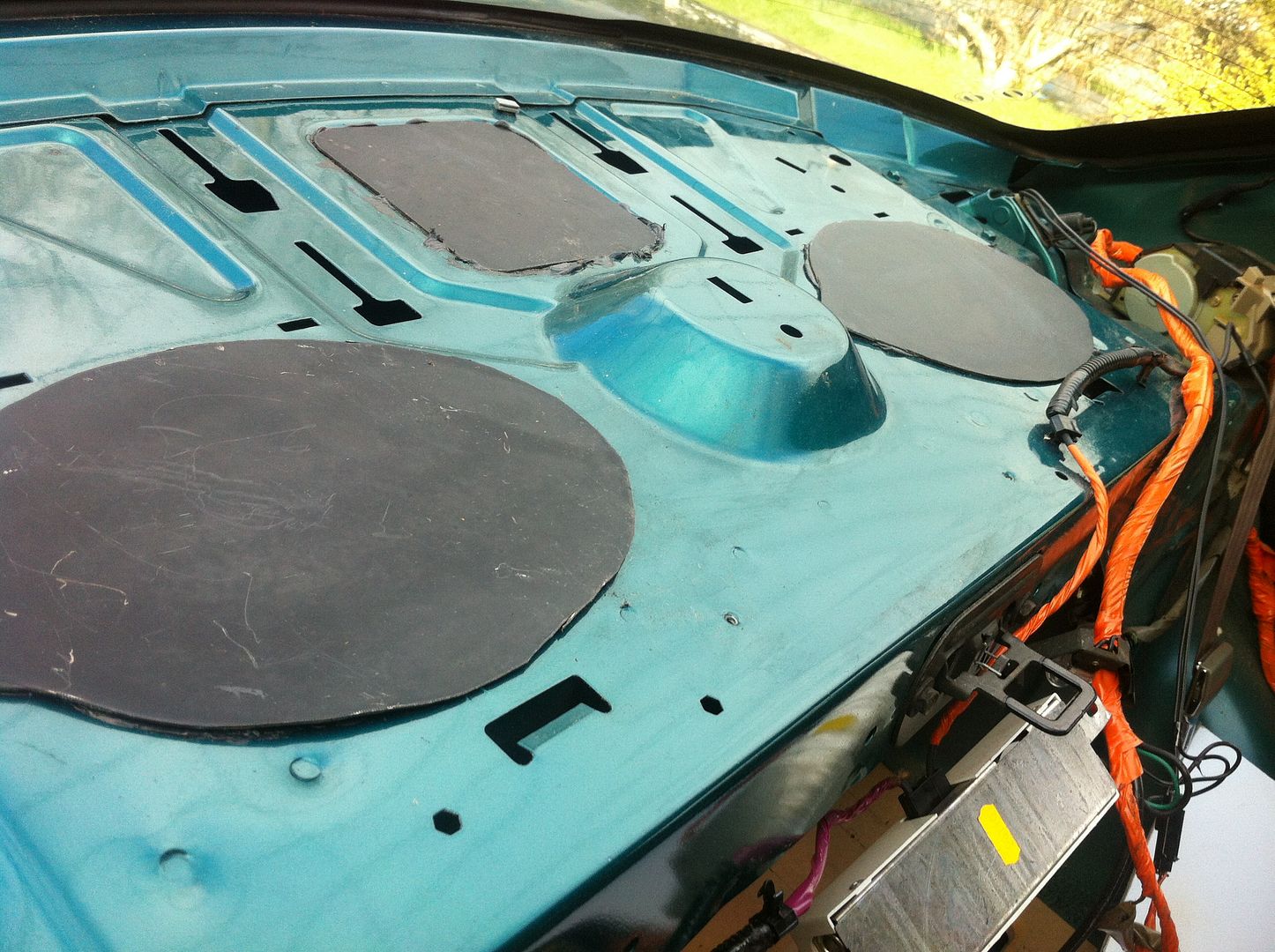

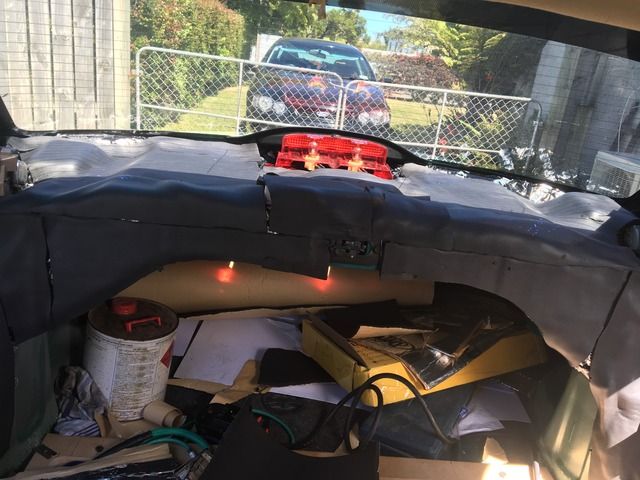

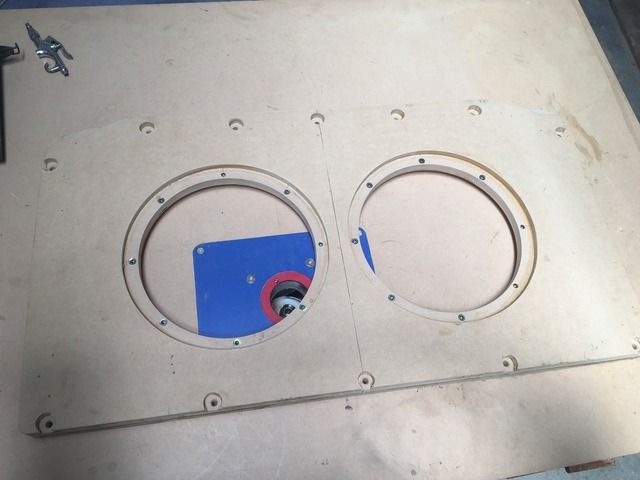

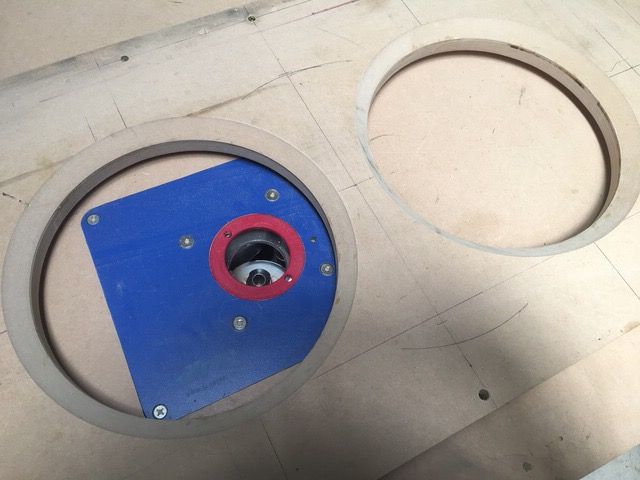

Subs - Image Dynamics IDQ12v2 D4 12" drivers, in Infinite Baffle on a PPI A300

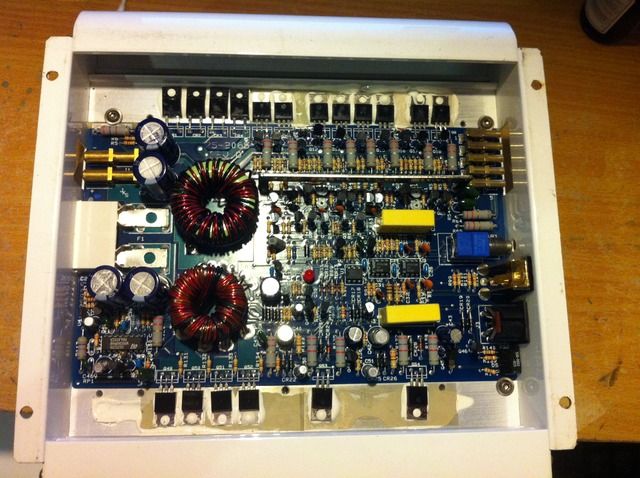

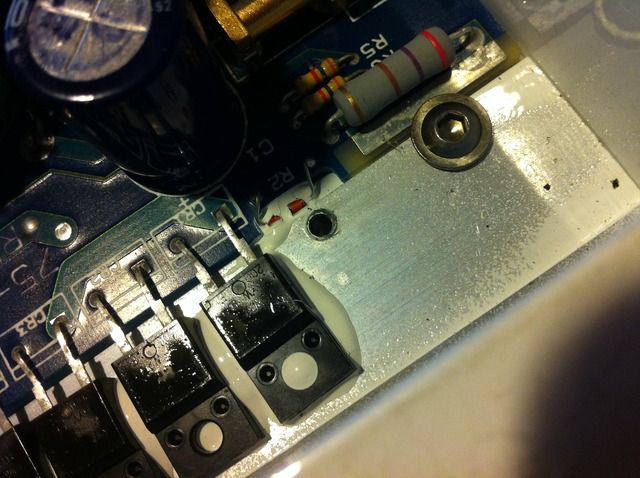

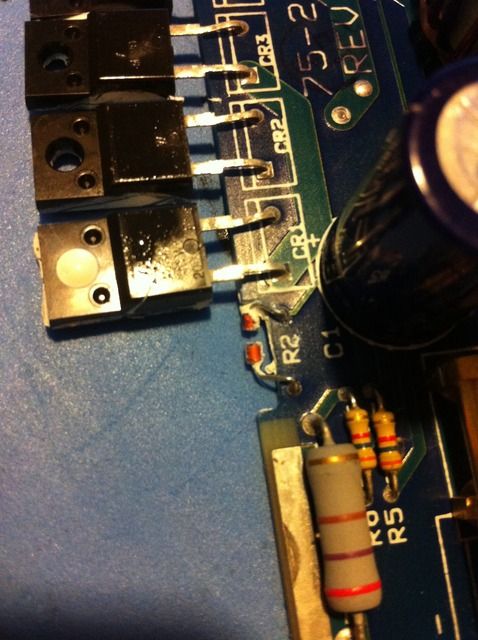

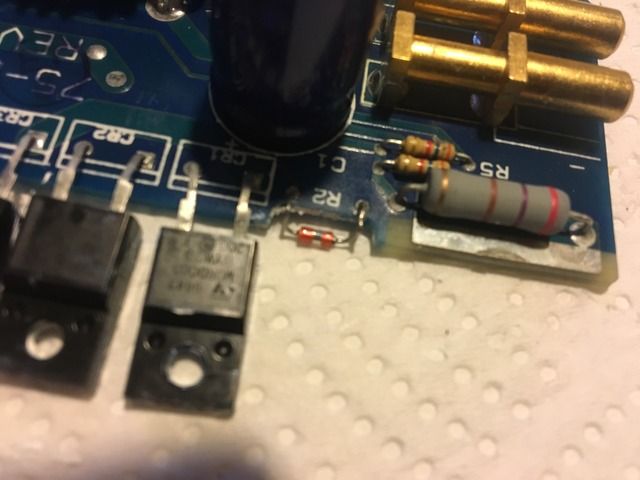

Really looking forward to getting this install done so I can finally listen to all these goodies rather than looking at them! Got a lot of work still ahead, besides the obvious install work, I'll be going through the Art amps with some fresh kapton tape and thermal paste.

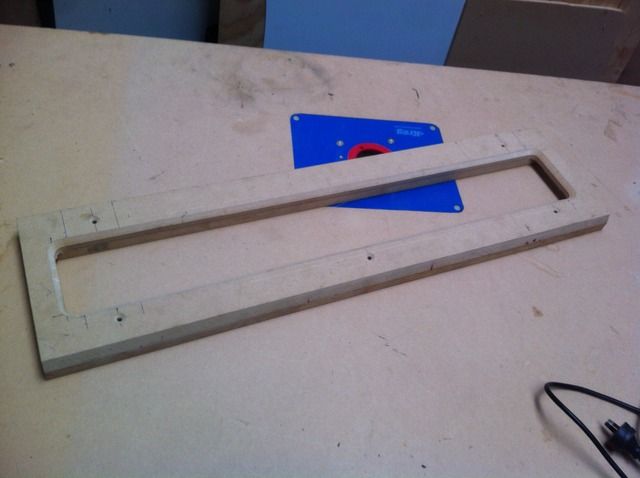

First things to be done are the headunit wiring harness and some 6-channel DIY RCA interconnects.

More to come soon!

The standard AC Delco cassette deck and speakers leave a lot to be desired aurally, so I figured it's time to dust off some of my old school car audio collection and put it to use where it belongs! So the plan is this:

Source:

Pioneer DEX-P1 with CDX-P1210 12 disc CD changer

Amplification/Speakers:

Highs - Image Dynamics CD-1 HLCD's with early fibreglass bodies on a PPI A100

Mids - Image Dynamics IDQ62 6.5" 2-Ohm drivers on a PPI A200

Subs - Image Dynamics IDQ12v2 D4 12" drivers, in Infinite Baffle on a PPI A300

Really looking forward to getting this install done so I can finally listen to all these goodies rather than looking at them! Got a lot of work still ahead, besides the obvious install work, I'll be going through the Art amps with some fresh kapton tape and thermal paste.

First things to be done are the headunit wiring harness and some 6-channel DIY RCA interconnects.

More to come soon!